Re-melt products

Re-melt purity products

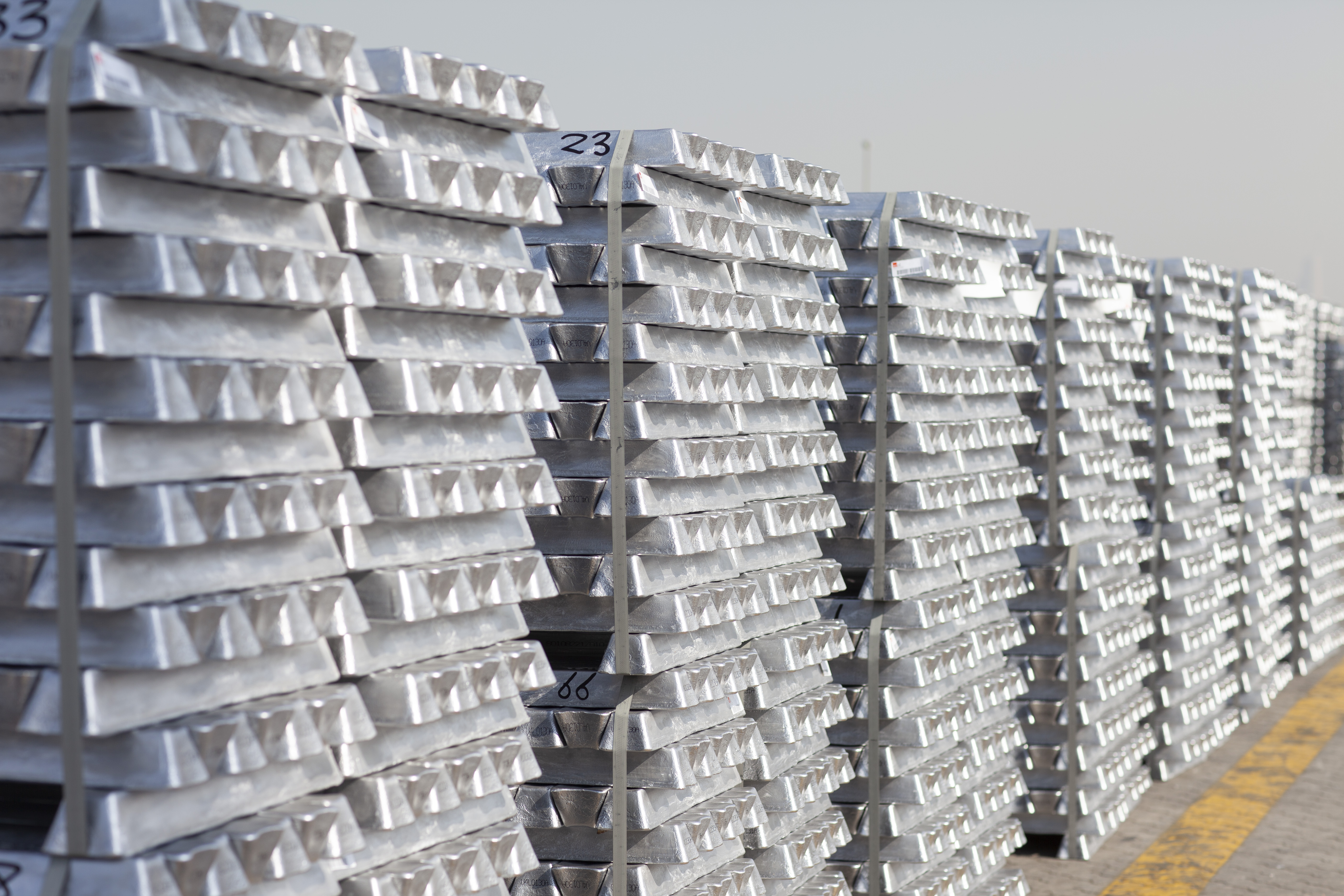

On average, pure and high purity ingots – cast as sow and standard ingots – account for about 15 per cent of EGA’s total annual production output. Superior processing and performance standards ensure that purity levels of up to 99.96 per cent are maintained and that customers’ exacting expectations are constantly met. Utilised in electronic and aerospace applications, where top quality high purity aluminium is critical to the successful manufacture of precision instruments, EGA’s high purity aluminium products are used in the manufacture of compact discs, computer hard drive memory disks, capacitors and other electronic components. They are also used in the manufacture of high reflectance, high performance alloys and cathodic protection.

Ranging from 99.84% to 99.96% aluminium content.

Specification can be customized to AA registered P1020, P0507A, P0303A, P0404A, P0304A, P0202A, P0102.

-

Standard Ingots (DUBAL)

- Weight

- 44 lb

- Dimensions

- 29” x 6.75” x 4.25 “ (length x width x height)

-

Standard Ingots (EMAL)

- Weight

- 48 lb

- Dimensions

- 29” x 7” x 4.5” (length x width x height)

-

Low Profile Sow Ingots

- Weight

- 1,500 lbs

- Dimensions

- 43" x 45.75" x 11.75" (length x width x height)

-

High Profile Sow Ingots

- Weight

- 1,100 lbs

- Dimensions

- 34" x 34" x 15" (length x width x height)

-

Standard Profile Sow Ingots

- Weight

- 1,500 lbs

- Dimensions

- 43.70" x 45.25" x 12.5" (length x width x height)

Re-melt foundry products

EGA is one of the largest and leading suppliers of foundry alloys to automotive manufacturers, where they are used in the manufacture of wheel rims, sub-frames, and suspension parts, cross members, engine blocks and engine cradles, among various other applications.

Consistency of product quality and high metal purity ensure the continuous demand for and success of EGA’s foundry products, which make up 27 per cent of the company’s total production output.

Alloys

A356.2, AlSi7Mg, AlSi9Mg, AlSi10Mg, AlSi11Mg, AlSiMgCu, Silafont 36 (available in both Sr modified and unmodified).

Packaging

Packed in bundles for convenient fork-lift handling.

-

Standard Ingots (DUBAL)

- Weight

- 44 lb

- Dimensions

- 29" x 6.75" x 4.25" (length x width x height)

-

Standard Ingots (EMAL)

- Weight

- 44 lb

- Dimensions

- 29" x 6.75" x 4.5" (length x width x height)

-

HDC Small Ingots

- Weight

- 17.5 lb

- Dimensions

- 29.75" x 2" x 3" (length x width x height)

-

Properzi Ingots

- Weight

- 22 lb

- Dimensions

- 28.75" x 4" x 2" (length x width x height)

-

B-Ingots

- Weight

- 22 lb

- Dimensions

- 28.75" x 4" x 2.75" (length x width x height)